Introduction to Toilet Flanges

Toilet flange play a critical role in bathroom plumbing installations. Understanding their function and installation is key to maintaining a secure and leak-free toilet. These fittings are essential for anchoring the toilet to the floor and ensuring a proper seal to the drainage system.

Importance of Proper Toilet Flange Installation

Correctly installing a toilet flange is crucial. It prevents leaks, odors, and unstable toilets. It also helps to avoid costly water damage and repairs. Always use the right tools and follow the manufacturer’s guidelines for the best results.

Functions of a Toilet Flange

A toilet flange connects the toilet to the drainage system and secures it to the floor. It holds the toilet in place, prevents movement, and creates a watertight seal with the wax ring. This seal stops leaks and blocks sewer gases from entering the bathroom.

Types of Toilet Flanges

Choosing the right type of toilet flange is essential for a secure and long-lasting toilet installation. There are several materials and styles to consider, each suited for different plumbing setups and preferences.

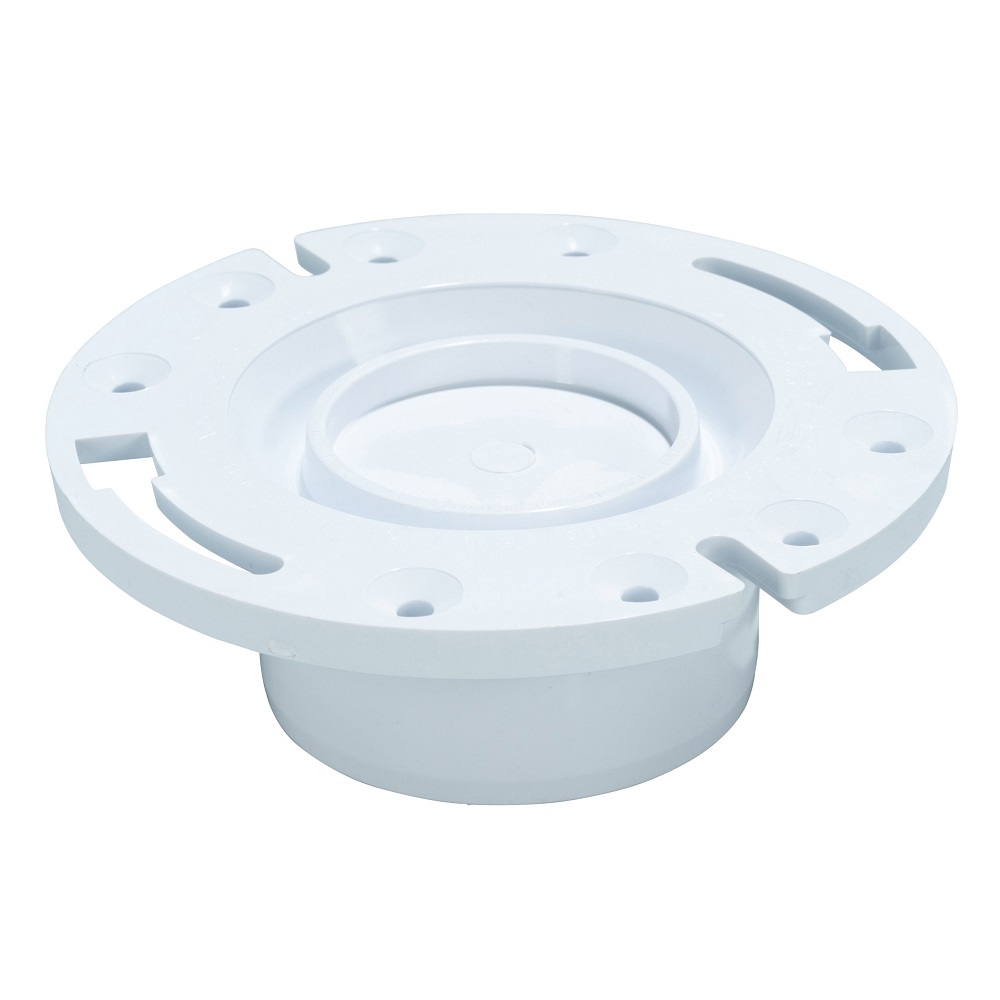

PVC or ABS Toilet Flanges

PVC and ABS flanges are popular due to their durability and corrosion resistance. They are lightweight, making them easy to handle and install. They fit well with plastic DWV (drain, waste, vent) pipes and are a budget-friendly option. Keep in mind to match the flange material with your pipe type.

Cast Iron Toilet Flanges

Cast iron flanges are ideal for heavy-duty use and are often used in commercial applications. This type of flange is sturdy and can handle a lot of wear and tear. It’s important to note that cast iron flanges usually cost more than plastic ones and are typically heavier, making them harder to install.

Brass Toilet Flange Options

Brass flanges offer a high resistance to corrosion and tend to be more durable over time. They’re a great option for older homes that may have brass piping in place. When installing brass flanges, skilled tradespeople are often required due to the more traditional connection methods needed.

Specialty and Offset Flanges

For challenging installations, where standard flanges can’t be used due to space constraints or pipe placement, specialty and offset flanges come into play. Offset flanges allow for the toilet to be installed away from wall obstructions, and specialty flanges can adapt to unusual angles or situations. Both options provide flexibility to ensure proper toilet placement and connection to the plumbing system.

Selecting the Right Flange Material

Choosing the correct toilet flange material is vital for a successful bathroom installation. It impacts durability, compatibility with your plumbing, and overall functionality.

Considerations Based on Pipe Material

The pipe material determines the type of toilet flange you’ll need. Match the flange material to your pipes for the best fit and a leak-free seal.

Benefits of Stainless Steel and Aluminum Flanges

Stainless steel and aluminum flanges resist rust and corrosion. They’re strong, durable, and provide a reliable seal.

Copper Flanges and Their Advantages

Copper flanges are long-lasting and resist bacteria growth. They’re a solid choice for health-conscious households and high-humidity environments.

Understanding PVC and Budget-Friendly Choices

PVC is cost-effective, tough, and won’t rust. It’s an excellent choice for those on a budget who need a reliable option.

The Hygienic Benefits of Brass Flanges

Brass flanges are hygienic due to their antimicrobial properties. They prevent bacteria buildup, making them a safe choice for your bathroom.

Installation Best Practices

Proper installation is vital for the secure, leak-free function of toilet flanges. Here are key practices to follow.

Ensuring Correct Flange Height

Set the flange height right to prevent leakage. It should sit on top of the finished floor, not below. Consider spacers if the height is off.

Using Rust-Proof Screws

Anchor the flange to the subfloor with screws that resist rust. Avoid drywall screws; they don’t last.

Keeping Bolt Slots Debris-Free

Keep bolt slots clear when installing flooring. Cover them with tape to block out dirt and mortar.

Utilizing Flanges with Knockout Plugs

For new builds or remodels, use flanges with knockout plugs. This lets you test the system and keeps sewer gases out during construction. The plugs also prevent debris from getting into the drain.

By following these best practices, you’ll ensure a solid and lasting installation. These steps help avoid common problems that could arise after setting up your toilet flange.

Common Issues and Repairs

When maintaining or replacing toilet flanges, you may encounter common issues. These range from unpleasant odors to wobbly toilets and water pooling around the base.

Identifying and Fixing Flange Problems

Be on the lookout for signs of trouble with your toilet flange. Unpleasant smells, a rocking toilet, or leaks at its base are key signs. Odors could mean a broken seal, while movement often indicates a loose or damaged flange. Water around the toilet usually points to a failing wax ring. If you spot rust or wear, consider a full flange replacement.

Repair Kits and Quick-Fix Options

Repair kits are available for quick flange fixes. These kits can mend cracks or breaks without replacing the entire flange. They’re user-friendly and come with simple instructions. For a proper fix, follow the kit’s steps carefully.

Solutions for Correcting Flange Elevations

Incorrect flange height can lead to leaks and instability. If the flange sits below the floor level, use spacers or extension kits. These products raise the flange to the right height for a secure, leak-proof fit. Always ensure the flange is level with or above the finished floor for best results.

Choosing the Right Material

When selecting a toilet flange, considering the material is just as important as its installation. Flanges are commonly made from PVC, ABS, or metal. While metal flanges are durable, they may corrode over time, especially in moist environments. PVC and ABS flanges are resistant to rust and decay, making them favorable choices for humid locations. Before making a selection, evaluate your bathroom’s environment and choose a material that guarantees longevity and stability.

Conclusion

As you navigate the diverse world of toilet flanges, it’s essential to keep two key components at the forefront: material and installation practices. Choosing the right flange and installing it correctly lays the groundwork for a well-functioning, leak-free toilet.

Recap of Flange Materials and Installation Tips

To encapsulate, the material of the flange should match the type of piping in your bathroom. PVC or ABS flanges excel in corrosion resistance and are budget-friendly. Cast iron flanges are robust, ideal for heavy use. Brass flanges offer durability and resist bacteria, making them perfect for health-focused environments.

Aluminum and stainless steel flanges withstand rust, offering solid and long-lasting connections. Copper flanges, apart from being durable, inhibit bacterial growth, a plus for humid climates.

When installing, ensure the flange height is correct, it must sit on or above the floor level. Utilizing rust-proof screws will keep the toilet stable for years to come. Keep bolt slots clear to avoid later complications, and consider knockout plugs to prevent debris during construction.

Should you encounter a wobbly toilet, unpleasant odors, or pooling water, address these with the right repair kit or consider replacing the flange if necessary. Using spacers can correct elevation issues, ensuring a snug and proper fit.

Toilets are a lasting part of your bathroom; ensuring they’re secured with the right flange is essential. Following these guidelines will help maintain a robust and sanitary bathroom, free from the common headaches associated with toilet installations.